Written by Stephen Day

Gas Safe Engineer

Updated: 6th February, 2026

Want to maximise your boiler efficiency in cold weather? Our guide provides tips on how to insulate your boiler pipes, keep up with routine maintenance, and choose the right boiler for your home. We compare advice from reputable sources to help you save money on energy costs and avoid unnecessary downtime.

Get a new boiler quote, save up to £550 per year (0% APR available).

As cold weather approaches, homeowners and facility managers must prepare their heating systems for optimal performance.

Maximising boiler efficiency during the winter months is essential to keep energy costs under control and ensure that heating is both consistent and reliable. This article will guide you through a scheduling strategy that aims to maximise the efficiency of your boiler during colder periods.

Understanding the intricacies of boiler systems is vital for making informed decisions and implementing best practices.

There are various types of boilers with different efficiency levels; selecting the appropriate boiler and fuel or power source can greatly impact overall efficiency. To optimise your system, it's crucial to be aware of the environmental impacts, temperature control, and heat exchange processes.

Get a quote in 60 seconds, fitted as fast as next day!

0% APR finance available.

Boiler efficiency is a crucial aspect when it comes to heating your home, as it indicates the proportion of energy converted into usable heat. By comprehending boiler efficiency, you can reduce energy consumption and save money on heating costs, particularly in cold weather. There are different methods of gauging boiler efficiency, such as ErP and SEDBUK.

A boiler's efficiency is measured in percentages, with higher percentages denoting greater efficiency. For instance, a 90% efficient boiler means that approximately 90% of the energy goes into heating your home, while the remaining 10% is lost as heat or utilised in powering the boiler.

The Energy-related Products (ErP) directive sets specific efficiency regulations for boilers sold within the European Union. This directive aims to reduce greenhouse gas emissions and improve energy efficiency standards. Under the ErP, boilers receive an efficiency rating from A+++ (most efficient) to G (least efficient), enabling consumers to make informed decisions when purchasing a new boiler.

Seasonal Efficiency of Domestic Boilers in the UK (SEDBUK) is another rating system used to evaluate boiler efficiency. SEDBUK rates boiler efficiency on a scale ranging from A to G. This system considers seasonal variations in temperature during its calculations to provide a more accurate indication of a boiler's efficiency throughout the year.

To maximise boiler efficiency, it is crucial to select an appropriate boiler size, ensuring no oversizing occurs. Additionally, regular maintenance, including annual servicing, is necessary to ensure consistent performance and prolong the boiler's lifespan.

An energy-efficient boiler, coupled with a well-designed scheduling strategy, can prove highly beneficial in significantly reducing energy costs and consumption during colder months. By understanding and incorporating boiler efficiency into your heating strategy, you will ultimately contribute to a more sustainable and cost-effective approach to home heating.

There are various types of boilers, and their efficiencies vary depending on their design and operation. This section will explore the following types of boilers: Combi Boilers, System Boilers, Heat Only Boilers, and Biomass Boilers.

Combi, or combination boilers, are all-in-one units that provide both hot water and space heating. They eliminate the need for a separate hot water cylinder and cold water storage tanks, saving space and reducing installation costs. Combi boilers operate at various efficiencies, with newer models often boasting higher percentages. Their compact design and ability to deliver hot water on demand make them a popular choice for many households.

System boilers work with a separate hot water storage cylinder, enabling them to provide a steady supply of hot water to multiple taps at once. They don't require a cold water storage tank, making them more space-efficient than regular boilers. While system boilers are generally less efficient than combi boilers, their ability to maintain a consistent supply of hot water makes them suitable for homes with multiple bathrooms and higher hot water demands.

Heat Only boilers consist of a separate hot water cylinder and cold water storage tank. They utilise a pump to transport hot water from the boiler to a storage tank and then through to the radiators or taps. Regular boilers typically operate at lower efficiencies compared to other types of boilers, but they can still be a suitable option for homes unable to accommodate a combi or system boiler.

Biomass boilers use renewable energy sources like wood pellets or chips to generate heat. By using a sustainable fuel source, they reduce reliance on non-renewable fossil fuels and can help lower carbon emissions. While biomass boilers generally have lower efficiencies compared to gas boilers, the environmental benefits may outweigh this drawback for homeowners looking to make a more sustainable choice.

In conclusion, it's essential to choose the most suitable boiler type for your specific needs and circumstances, carefully considering factors like efficiency, space requirements, and hot water demands.

In order to maximise boiler efficiency in cold weather, it is essential to consider various fuel and power options. These options have different characteristics in terms of cost, carbon emissions, and availability, which can influence the performance of a boiler.

Natural gas is a popular choice for heating systems due to its abundance, relatively low cost, and ease of use. Gas boilers have a minimum performance standard of 92% seasonal space heating efficiency, as required by the European rating system (ERP)¹. Utilising effective control measures, such as weather compensation, can help maintain low return water temperatures, which in turn increases the efficiency of gas boilers.

Electricity can also be used to power boilers or heat pumps in heating systems. Although typically more expensive per unit of energy than natural gas, electric heating options often have a lower carbon footprint, especially if the electricity is generated from renewable sources. However, in locations where the electricity grid relies heavily on fossil fuels, electric heating options may not be as environmentally friendly.

Biomass, often in the form of wood pellets or chips, can be used as a sustainable and low-carbon fuel option for boilers. However, biomass boilers require significant storage space for the fuel and have higher upfront costs than conventional gas boilers. When considering biomass, it is important to source the fuel from sustainably managed forests to minimise the overall environmental impact.

To sum up, maximising boiler efficiency in cold weather is largely influenced by the chosen fuel and power options. Natural gas offers affordability and established technology, while electricity and biomass provide greener alternatives.

During cold weather, the efficiency of a boiler can be significantly impacted by various factors, including outside temperature fluctuations and weather compensating controls. To maximise your boiler's efficiency throughout the colder months, it is imperative to have a well-planned scheduling strategy in place, focusing specifically on these external elements.

Weather compensation controls play a vital role in boiler efficiency; they operate by maintaining the boiler at the lowest possible flow temperature while still providing adequate output to the heat emitters. This strategy ensures optimal operation in condensing mode, ultimately conserving energy and enhancing boiler efficiency. When accounting for fluctuations in temperature, these controls prove particularly helpful, as they modulate the boiler's output in response to weather variations, preventing unnecessary energy usage.

Furthermore, the ambient temperature can influence the boiler's flow setpoint or the temperature in separated zone circuits. As a result, dynamically controlling the flow water temperature feeding the building heating system using weather compensation is essential. This practice adjusts the flow setpoint or the temperature in separate zone circuits as outdoor temperatures increase, aiding in overall efficiency.

In summary, to maximise boiler efficiency during cold weather, it is crucial to implement scheduling strategies that account for factors such as temperature fluctuations and the use of weather compensation controls. Making use of these systems allows you to optimise your boiler's performance, cutting down energy consumption and potentially reducing costs.

Modern, efficient boilers often operate in condensing mode, harnessing a heat exchanger to recover heat from the flue gases. This heat is then used to warm up incoming cold water before it goes into the boiler's main heat exchanger. By doing so, the boiler uses less energy to heat the water, enhancing its efficiency.

Air Source Heat Pumps are designed to boost boiler efficiency in colder climates. These devices extract heat from the ambient air, even in low temperatures, and channel it into the building's heating system. Functioning oppositely to a refrigerator, an ASHP consists of an evaporator coil, a compressor, and a heat exchanger.

The evaporator coil captures heat from the air.

This heat causes the refrigerant to compress, increasing its temperature.

The now-warm refrigerant travels through the heat exchanger, imparting its heat to the indoor heating system.

Given their operation, ASHPs often produce more energy than they use, marking them as a highly efficient heating choice.

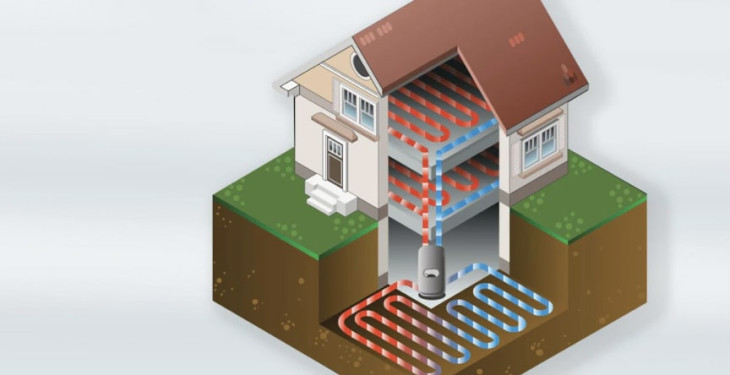

Unlike ASHPs, Ground SHPs draw heat from the ground. Since the ground offers a steadier temperature year-round, GSHPs are particularly effective in colder regions. These systems have underground pipes filled with a special fluid that collects heat from the earth3.

Once inside the heat pump, a heat exchanger transfers this gathered heat to the building's heating system. As with ASHPs, GSHPs frequently produce more heat energy than they take in, resulting in energy-efficient heating.

In summary, leveraging heat exchange technologies in boilers and heat pumps, like condensing boilers, ASHPs, and GSHPs, can lead to optimised heating strategies and greater efficiency in chilly conditions.

In order to maximise boiler efficiency in cold weather, it is essential to optimise heating systems. This can be done by implementing a scheduling strategy that considers various factors such as the heating system type, heating requirements, and heating output. This section will discuss two popular heating systems: Radiators and Underfloor Heating.

Radiators are a common home heating option that are efficient in distributing heat evenly in a room. To optimise a radiator-based heating system, consider the following steps:

Adjusting radiator valves: Thermostatic radiator valves (TRVs) allow control over the temperature of individual radiators. Ensure that they are properly adjusted to maintain a comfortable and energy-efficient ambient temperature.

Balancing radiators: When multiple radiators are part of a heating system, balancing ensures they heat up evenly and work efficiently. This prevents overworking the boiler and saves energy.

Maintaining radiator efficiency: Regularly bleed air from radiators to maintain maximum heat output. Also, avoid covering radiators with large items such as furniture, as this can block heat distribution.

Scheduling: Implement a heating schedule that meets each room's heating requirements and outside temperature, thus optimising energy usage.

Underfloor heating systems are a comfortable and efficient option for homes, providing a gentle and even distribution of heat. To maximise the performance of underfloor heating systems, adopt the following strategies:

Optimising floor materials: Different flooring materials have different heat conductivity. Insulating underfloor heating with high-conductive materials like screed or tile can improve heat distribution and efficiency.

Zoning: Divide your home into separate heating zones with individual thermostats, tailoring the heating output to each area's specific needs. This ensures energy is used efficiently.

Scheduling: Just like with radiators, implement a heating schedule based on each zone's heating requirements and outside temperature.

Gradual heating: Underfloor heating systems have a longer response time when adjusting temperatures. Therefore, ensure that changes to the heating schedule are gradual to prevent short cycling of the boiler, thus increasing its efficiency.

By understanding the unique characteristics and requirements of radiators and underfloor heating systems, we can optimise their performance to maximise boiler efficiency during cold weather.

Implementing control and scheduling strategies is an integral aspect of maximising boiler efficiency, particularly during cold weather. A well-designed control strategy enables the boiler to respond effectively to indoor and outdoor temperature changes, thereby maintaining a comfortable environment and reducing energy consumption.

A common and essential component of a control strategy is the thermostat. The thermostat regulates the indoor temperature by sending signals to the boiler when the temperature drops below a predetermined set point, resulting in the boiler firing and producing heat. Programmable thermostats offer flexibility in setting the desired temperatures and time periods, allowing users to fine-tune the heating schedule based on their specific needs and occupancy patterns.

When devising a control strategy, it is crucial to consider the various heat demands across the building. For instance, partitioning the building into separate zones and equipping each with an individual thermostat may deliver significant energy savings. This approach enables the independent control of temperature and scheduling in each area, allowing for a more personalised heating experience and better overall efficiency.

Another key factor is the utilisation of weather-based boiler controls. These systems, known as outdoor reset controls, adjust the boiler's temperature in response to outdoor climate fluctuations. By continuously monitoring external temperatures, these controls can modulate the boiler output accordingly, ensuring optimal performance while simultaneously reducing energy waste.

Furthermore, in larger buildings or complexes that employ multiple boilers, employing a comprehensive control strategy can significantly improve efficiency. Implementing a lead-lag control system—where the operation of boilers is alternated or modulated to match demand—can result in better load distribution, reduced boiler cycling and enhanced long-term performance.

In conclusion, maximising boiler efficiency during cold weather relies heavily on implementing tailored control and scheduling strategies. By incorporating programmable thermostats, zoning, outdoor reset controls, and lead-lag systems, organisations can achieve greater energy savings and improve overall boiler performance.

Energy efficiency plays a vital role in reducing carbon emissions and moving towards a zero carbon heating future. Optimising boiler efficiency during cold weather is crucial, as it can directly impact the environmental footprint of a building.

Boilers that are energy efficient consume less fuel and produce fewer emissions, minimising their adverse effect on the environment. The Energy-related Products Directive (ErP) and the Medium Combustion Plant Directive (EU 2015/2193) set efficiency standards for boilers with output powers of less than 400kW in the UK. These regulations encourage the installation of sustainable heating solutions, helping to reduce the overall greenhouse gas emissions.

Implementing a scheduling strategy can significantly improve boiler efficiency in cold weather, lessening the environmental impact. Properly scheduling boiler usage reduces the frequency of on-off cycling, which leads to lower energy consumption and carbon emissions. Moreover, this strategy can extend the life of the boiler system, thereby reducing waste and environmental harm from manufacturing and disposal.

Periodic real-time monitoring can detect performance degradation and efficiency curve changes, enabling timely corrective actions to be taken. This practice ensures that boilers maintain optimal efficiency ratings and contribute to the reduction of carbon emissions in the long term.

In conclusion, maximising boiler efficiency in cold weather through scheduling strategies and regular monitoring is essential to minimise carbon emissions and lessen the environmental impact. By doing so, the heating industry can effectively contribute to the UK's goal of achieving zero carbon heating solutions.

Heat recovery is a crucial method that can be employed to maximise boiler efficiency in cold weather conditions. By utilising the heat generated from the flue gas, which would otherwise be wasted, boiler efficiency can be improved. This process repurposes the heat, and in turn, conserves energy and reduces the overall costs of operation.

One of the known heat recovery technologies is passive flue gas heat recovery, which significantly enhances the performance of combination boilers. In industries, techniques such as economisers and waste heat boilers are also used to retrieve heat from high-temperature flue gas in power plants.

To optimise the boiler efficiency, it is crucial to understand and manage the boiler flow temperature properly. The boiler flow temperature refers to the temperature of the water circulating in the central heating system. This temperature is related to the heat exchange process between the hot exhaust gas and the water inside the boiler.

By adjusting the boiler flow temperature, the efficiency of a heating system can be improved. A higher flow temperature means an increased amount of heat exchange with the flue gas, leading to more effective heat recovery. On the other hand, if the flow temperature is too high, it may result in higher heat losses, which negatively affects the efficiency of the boiler.

Boiler flow temperature management can be achieved through several best practices:

Regularly monitor boiler operation parameters, including flow temperature, to ensure the system is running within optimal ranges.

Use appropriate insulation materials for pipework and other components to minimise heat losses in the system.

Implement advanced control systems that dynamically adjust the boiler flow temperature according to the actual heating demands and outdoor conditions.

In conclusion, heat recovery and boiler flow temperature play a vital role in maximising boiler efficiency during cold weather. By using innovative technologies and following best practices, the effectiveness of a heating system can be significantly improved, leading to lower energy consumption, reduced costs and a more sustainable performance.

Optimising boiler efficiency during cold weather can lead to significant reductions in energy bills and running costs. By implementing a strategic scheduling approach for boiler usage, homeowners and businesses can achieve considerable savings in energy consumption.

Adjusting the boiler flow temperature can be a practical approach to increasing efficiency. Combi boilers, for instance, are typically set to a flow temperature between 70C and 80C upon installation. However, lowering the flow temperature to around 60C may result in approximately £100 in savings per year. It's crucial, though, to ensure that the lowered temperature still provides adequate heating and hot water for the inhabitants.

Investing in proper insulation can improve the overall effectiveness of a heating system, minimising heat loss and reducing the boiler's workload. Ensuring wall, floor, and loft insulation meet recommended standards can contribute to even greater savings over time. Additionally, using draft excluders and double glazing windows are effective ways to retain warmth and cut energy consumption.

To add to this, adopting energy-efficient habits can enhance cost savings even further. They include:

Monitoring the thermostat settings: Ensuring that the thermostat is set according to the specific requirements of different rooms or times of the day can prevent excessive heating and energy wastage.

Utilising timers: Timers enable the heating system to switch on and off as required—maintaining a comfortable temperature while avoiding unnecessary use of energy.

Lastly, exploring the possibility of upgrading to a more efficient boiler can drastically decrease energy consumption and costs. Modern condensing boilers, for example, are designed to be considerably more efficient than older models due to advancements in technology and stricter regulations.

In conclusion, implementing a strategic scheduling approach to maximising boiler efficiency involves numerous factors, from adjusting flow temperature to upgrading insulation and employing energy-efficient habits. By carefully considering and addressing these aspects, homeowners and businesses can make a substantial impact on their energy consumption and expenditures during cold weather.

Investing in insulation is a key factor in maximising boiler efficiency. Enhancing insulation in your home reduces heat loss, thereby allowing the boiler to work less and maintain a consistent temperature. Consider insulating walls, roofs, and floors, and use draught proofing around windows and doors to prevent cold air from entering and warm air from escaping.

Choosing the right boiler installation is crucial for maintaining efficiency, especially during cold weather. Ensure that your boiler has an energy-efficient rating of A or better, as these models operate at 90% efficiency or higher, whereas G-rated boilers perform at just 70% efficiency. Proper installation by a qualified professional is vital, as incorrect installation can lead to reduced efficiency and potential issues down the road. Additionally, locating the boiler in an area with proper ventilation and minimal exposure to the elements can help maintain its efficiency.

To maintain your boiler's performance, schedule regular maintenance and servicing with a Gas Safe boiler engineer. This expert can identify and address any issues impacting efficiency, which helps to prevent larger problems from developing. Regular servicing can also extend the life of your boiler, reducing the likelihood of breakdowns during cold weather when it is needed most. Furthermore, pay attention to your boiler's pressure gauge; a healthy pressure should read around 1.5 bar. If the pressure is low, consult a professional for assistance in correcting it.

Lastly, ensure that your heating system is properly designed and programmed. A well-thought-out scheduling strategy can optimise your boiler's efficiency during colder periods by matching heating demand with supply. Implementing an effective timer and thermostat can help you manage temperature settings and heating durations more efficiently.

By following these tips, you can maximise your boiler's efficiency and performance, especially during colder weather, ultimately leading to lower energy bills and a more comfortable home environment.

Check out new boiler costs

Last updated: 6th February, 2026

Written by Stephen Day

Gas Safe Engineer at iHeat

Stephen Day is a Gas Safe registered and FGAS certified engineer with over 20 years of hands-on experience in the heating, cooling, and renewable energy industry, specialising in boiler installations, air conditioning, and heat pump systems.

LinkedInArticles by Stephen Day are reviewed by iHeat’s technical team to ensure accuracy and reliability.

19th February, 2026

Selecting the appropriate boiler for your London home involves understanding the different...

Read Article

Read Article

19th February, 2026

A typical Annual Boiler Service includes a visual inspection to identify any obvious fault...

Read Article

Read Article

19th February, 2026

Boiler servicing comprises a set of inspections and tests conducted by a qualified enginee...

Read Article

Read Article

No obligation. Takes less than 60 seconds.