Written by Stephen Day

Gas Safe Engineer

Updated: 5th February, 2026

When it comes to Boilers, there can be some confusing jargon. Just what exactly is a Boiler Filling Loop?

Get a new boiler quote, save up to £550 per year (0% APR available).

A boiler filling loop is an incredibly useful tool that is often used during boiler installations and boiler fixes.

In this guide, we’re going to be explaining exactly what a boiler filling loop is, how it works and answering some of the most commonly asked questions about these handy tools.

Get a quote in 60 seconds, fitted as fast as next day!

0% APR finance available.

A boiler filling loop is a tool used to provide a temporary connection between the boiler and the mains water supply, allowing you to re-pressurise your boiler and fill your heating system with water.

Fortunately, even if you don’t have much experience fixing boilers, a boiler filling loop is a rather simple tool to use.

If your boiler pressure has dropped below the recommended bar, you will need to top up the pressure to ensure your boiler operates as it should.

Anything below half a bar can have significant consequences on how your boiler operates and could lead to long term issues if left unfixed, so it’s absolutely essential to know how to top up the pressure if it does drop.

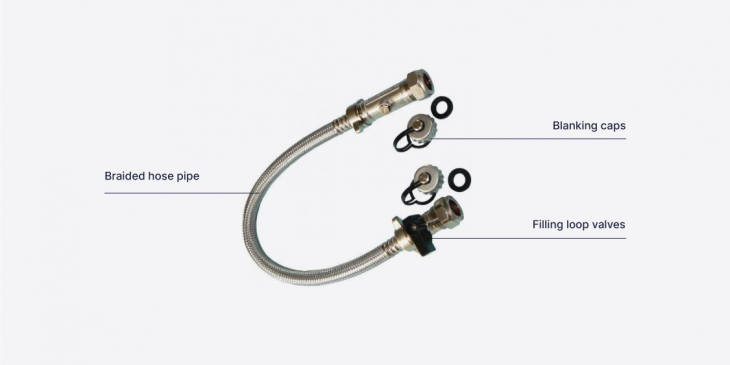

Braided hose pipe

Filling loop valves

Blanking caps

Before attempting to re-pressurise your boiler, make sure to check that the filling loop valves are in the ‘off’ position before continuing (see image below).

Attach the filling loop valves to either end of the braided hose pipe.

Connect the boiler or the water mains with the filling loop valves.

Using your hands, ensure the filling loop is fixed firmly in place onto the braided hose pipe.

To turn the valves into the ‘on’ position, turn one valve so that it matches the direction of the pipe. This should allow water to start coming from the mains into your central heating system.

As the water enters your central heating system, the reading on the boiler pressure gauge should start to rise.

Once the gauge reaches the recommended bar for your boiler (usually around 1.4 bar), turn the valves back so they are once again closed.

Make sure to disconnect the filling loop from your boiler once you have finished using it.

This step is incredibly important as, although it may seem like a good idea to leave it in place for future use, this is actually against regulations as it could cause irreparable damage if left connected.

A boiler sometimes loses pressure by itself over time and it isn’t usually a cause for concern so long as it doesn’t keep on dropping.

Persistent low boiler pressure can be caused by two major problems: a leak or an issue with the boiler itself.

If you think your central heating system may have a leak, or if you suspect there is an issue with your boiler that may be causing the pressure to constantly drop, don’t hesitate to call a Gas Safe registered engineer to come and take a look.

Different boiler brands and models have different boiler pressure recommendations, but most boilers are designed to be around 1 and 2 bar units.

Make sure to always check your manual before you make an adjustment to your boiler pressure.

Taking the pressure too high or low, even for a second, can waste fuel and might end up with you losing control of your boiler entirely.

You can check to see if your boiler pressure is too high or low by taking a look at your boiler pressure gauge and ensuring it is within the recommended pressure range for your individual boiler model.

Certain electronic boiler models also use error codes to tell you about major problems, such as a change in boiler pressure.

Here are some of the most common boiler brand error codes relating to boiler pressure.

Viessmann Boiler Pressure Error Codes:

Fault Code C1 = Differential air pressure.

Fault Codes B9, ED, F0, F-E5, F-EC, F-ED, F-EE, F-EF, F-FD, F-FF = Maximum pressure limiter issue.

Fault Code F5 = Faulty gas pressure switch.

Fault Codes EE and EF = Faulty air pressure switch.

Fault Code 0F = Service required.

Alpha Boiler Pressure Error Codes:

Fault Code 1 = General ignition failure.

Fault Code 2 = Low pressure in the primary system.

Fault Code 61 = Incorrect system pressure, air in the pump.

Fault Code 0A37 = Insufficient pressure and flow (switches the boiler off automatically).

Fault Code 0E37 - Insufficient system pressure.

Worcester Boiler Pressure Error Codes:

Fault Code E9 = Safety limiter.

Fault Code A1 = Dry pump.

Fault Code F0 = Major internal error.

Fault Code CE 207 = Low water pressure.

Fault Code H07 = Low water pressure that is impacting performance.

Fault Code 1065 B = Pressure sensor is defective.

Fault Code 1970 B = Sudden, rapid drop in pressure.

If a high or low boiler pressure is left untreated for an excessive amount of time, you could end up destroying a large part of your heating system, especially if the boiler relies on the constant movement of water to function properly.

One main reason for this is because water regulations strictly prohibit used water from flowing back into the mains.

This is because if you water that runs through your radiators accidentally comes out of the shower and taps then you could be exposed to a highly contaminated water source!

Typically, the engineer that installs your boiler will leave it nearby so you can easily access it should any issues arise later down the line.

However, if you are unable to find it, you can easily find a replacement online or at your local DIY shop.

A new boiler filling loop costs between £7 and £20 - a worthwhile investment to ensure you have one on hand should you ever need it.

If your boiler is over 15 years old and you find that it keeps losing pressure, it may be time to get a new efficient boiler to replace it.

At iHeat, we install a wide range of high quality A-rated boilers from top brands such as Worcester Bosch, Viessmann, Alpha and Ideal.

Get a free, fixed quote today!

For more advice and information about your boiler, check out our handy boiler guides.

Boilers can be a daunting purchase for many people as they’re an appliance with a lot of responsibility, providing heat for you and your family is something you want to get right. Boilers aren’t exactly a quickly disposable item either, potentially lasting you a decade.

Effectively, new boiler cost can be split into two segments: the first is the actual boiler itself (unit price), and the second is the cost of the boiler being installed (set up) in your property by an expert engineer.

Here at iHeat, we want to remove all of this undue stress and make the decision making process of upgrading to a new central heating system, as easy as possible.

Installation Type | Price (inc VAT) | |

Combi to combi swap | £1,845 | |

System to combi conversion | £2,499 | |

New boiler install | £2,899 | |

Back boiler to a combi | £3,299 | |

System to system | £1,945 |

Last updated: 5th February, 2026

Written by Stephen Day

Gas Safe Engineer at iHeat

Stephen Day is a Gas Safe registered and FGAS certified engineer with over 20 years of hands-on experience in the heating, cooling, and renewable energy industry, specialising in boiler installations, air conditioning, and heat pump systems.

LinkedInArticles by Stephen Day are reviewed by iHeat’s technical team to ensure accuracy and reliability.

13th February, 2026

Boiler energy efficiency refers to how well a boiler uses its fuel to generate heat. This...

Read Article

Read Article

12th February, 2026

This Valentine’s Day we want to let you in on a dirty little secret…

Read Article

Read Article

12th February, 2026

In this guide, we’ll be answering some of the most frequently asked questions about what h...

Read Article

Read Article

No obligation. Takes less than 60 seconds.